| |

|

|

|

|

|

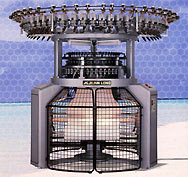

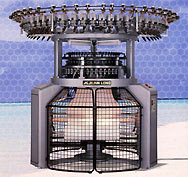

J LS- E M

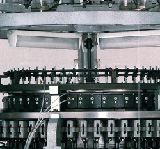

In combination with latest technology of computer, knitting

and machinery.

A new innovation, JLS-EM,

full electronic mesh knitting machine is able to produce mesh

fabrics by special cam design and yam feeder.

By feeding 2 kinds of. yarn with different specifications into

yarn feeders , Computerized actuators perform the movements

to make the fabric patterns with unlimited versatility.

The fabrics produced by JLS-EM

is convertible to produce both mesh and single Jacquard fabrics

with out changing any mechanism .Slightly adjustment in sinker

cam block is able to get the alternatives of both functions.

|

|

|

¡½ELECTRONIC

CONTROLLER

With the best Micro-Processing technology enabling the Electronic control

system together with floppy disk drive and touch panel, in the frame

of the machine itself. The controller with the functions of data input¡A¡O

Running Test, Counter Reset, Utility and Color Change. The pattern data

are read into the controller and transform the command into the mechanical

movements by the actuator. |

|

|

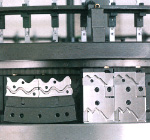

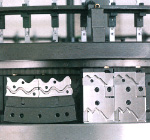

¡½CAM

DESIGN

The Cams, most significant portion, is

made of special alloy steel and carved by CNC milling machines by

the aid of Auto-cad design. Precisely heating treatment ensure its

hardness and durable among heavy friction.

Cam design is subdivided into individual segments and is exchangeable

for special pattern cams.

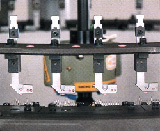

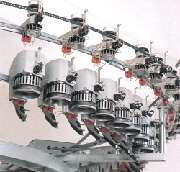

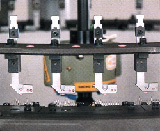

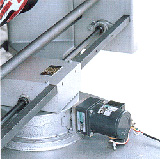

¡½ACTUATOR

The defect of the traditional coil magnet actuator is limited by the

sensible heat from the character of wire coil. The electric current

create heating conduction to restrict the speed on the needle selection.

To rectify this matter ,JLS-EM series use the advanced ceramic Actuator

as standard which ensure the stable running and the Electricity consumes

9O% less than the old generation actuator and no more heat flow to

restrict the performance on needle selection.

16 steps of the Actuators provide the sufficient space and more movement

flexibility on needle selection. Reset function on the Actuator adopt

the mechanism of forced slider to ensure the reset movement perfectly

and prevent the exhausted elasticity on spring type of Actuator.

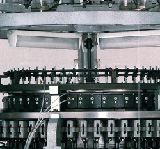

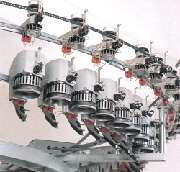

¡½ THE

BRACKET OF SYNCHRONlZED YARN KNITTING SYSTEM

The bracket set is designed for adjusting all yam knitting system

in the same time.

¡½NEW

ELECTRONIC CONTROL PANEL

It is more sensitive than traditional control panel which can supervise

abnormal status of knitting machine and show different related numerical

data , it is convenient for handling the best production status and

speed (RPM), in order to keep the machine under normal operation.

¡½STORAGE

FEEDER (SFT/SFE)

The essential advantage of the SFT (SFE) is that it compensates for

tension variations resulting form the bobbin make-up, Yarn path, etc.

The use of various type of tension ring ensures a range of constant

yarn take-off tensions.

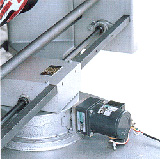

¡½MOTORIZED

TAKE UP SYSTEM

This machine is equipped with a torque motor, And is driven by mechanical

transmission.

It can simultaneous pack up and roll up the single-side, double-sided,

and jacquard fabric.

The system steadily execute fabric-pulling and fabric-rolling without

affect yam tension.

|

| SPECIFICATIONS |

| DIAMETER |

JLS-EM

30-3P |

| NO. FEEDS |

48F |

| GAUGES |

12G |

14G |

16G |

18G |

20G |

22G |

24G |

26G |

| NEEDLE NO. |

VO88.80.G01 |

VO88.65.G01 |

VO88.48.G01 |

VO88.41.G015 |

| R. P. M. |

15-25

RPM |

| MOTOR |

7.5HP |

| PACKING |

Dimension =LxWxH(2300mmx1950mmx2200mm)

Gross weight¡G=2900KGW |

¡@ |

|

|

JIUNN LONG MACHINE

CO., LTD.

No.13-2, Wu Lin St., Shu Lin District, New Taipei City, Taiwan, ROC

Tel: 886-2-26841580~4 Fax: 886-2-26841730 E-mail:webmaster@jlm.com.tw |

|

|